Spray Drying

Scroll

Haverhill’s Legacy of Spray Drying Excellence

The Haverhill, UK site is fully licensed for Investigational Medicinal Products (IMP) and also holds a commercial Manufacturer’s/Importer’s Authorization (MIA) issued by the MHRA. Additionally, the site is certified to ISO 14001 and ISO 50001 standards.

Given its diverse commercial product mix and the broad range of markets served globally, the Haverhill site has a long history of interaction with various regulatory agencies. Since 2015, it has successfully passed eleven audits conducted by local and foreign regulatory bodies, with zero critical observations. Currently, with our local regulatory authority, the MHRA, we are classified in their lowest risk tier due to our consistently high inspection performance and the absence of critical observations recorded over the past decade.

In addition to a strong emphasis on quality, the Haverhill site has a proven track record of environmental performance, with significant achievements in carbon reduction, recycling, and reducing process mass intensity.

Aqueous & Solvent-Based Spray Drying

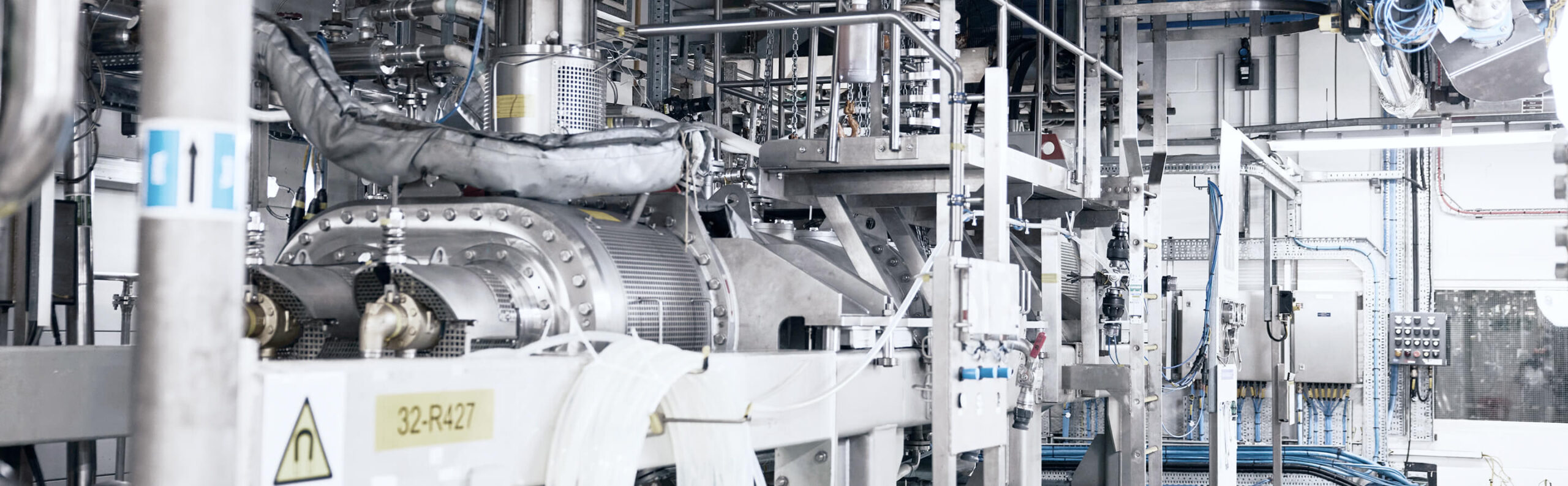

Codis has three cGMP spray drying centers: two for products manufactured from aqueous feedstocks of organic or mineral-based product compositions, and one for products processed from solvent-based product feedstocks.

-

Aqueous-Based Spray Drying

Learn more about Aqueous-Based Spray DryingThe Haverhill, UK, aqueous spray drying center features three large-scale GEA tall form dryers (TFD), ranging in size from TFD25 (100 kg water/hr evaporative capacity) to TFD400 (1,500 kg water/hr evaporative capacity). Our Seymour, IN, USA facility conducts, primarily for mineral-based products, aqueous-based spray drying at commercial scale and is capable of producing over 5,000 metric tons of material annually.

-

Solvent-Based Spray Drying & ASDs

Learn more about Solvent-Based Spray Drying & ASDsCodis enhances the oral bioavailability of DCS Class 2a, 2b, and 4 compounds through spray drying of amorphous solid dispersions under cGMP conditions utilizing a Procept SD1 or GEA PSD-2. Our closed-loop solvent spray dryers operate under inert nitrogen with twin-fluid and high-pressure atomization. Compatible with volatile solvents—including acetone, methanol, ethanol, and dichloromethane—our systems deliver optimized ASD performance and stability.

The Right Scale for Every Phase & Every Program

From product for feasibility studies to multi-ton commercial runs, Codis offers a seamless continuum of capacity.

Data Science & Modeling

Our Modeling Toolbox Includes

Mechanistic models

Statistical & machine learning models

Process Analytical Technology (PAT) informed inline sensing & multivariate control

Technology Transfer

We transfer in processes from innovator organizations or other CDMOs, then scale them using a risk-based, QbD approach. We incorporate all previously generated product and process knowledge, addressing gaps as necessary. Using this as a base, we scale from Process Design through Process Performance Qualification (PPQ) and Continued Process Verification (CPV). Ultimately, our customers achieve reliable, inspection-ready supply faster without risking product supply.

Our Technology Transfer Protocols Include

Risk assessment

Technology gap analysis

Process and analytical method transfer

Stability assessment

Quality control and release testing

Validation

Regulatory submission support

Discover Codis

Explore how Codis applies its expertise in spray drying, microencapsulation, continuous granulation, final dosage forms, and functional products to meet your formulation and manufacturing needs.

Codis Insights & Updates

Stay current with the latest in particle engineering science and Codis articles and resources.

Connect with us to explore how our particle engineering, commercial spray drying, formulation, and advanced manufacturing capabilities deliver high-quality, dependable supply for even the most challenging products.