Solvent-Based Spray Drying and Amorphous Solid Dispersions (ASD)

Scroll

Amorphous Solid Dispersions Core Capabilities

Discover Codis

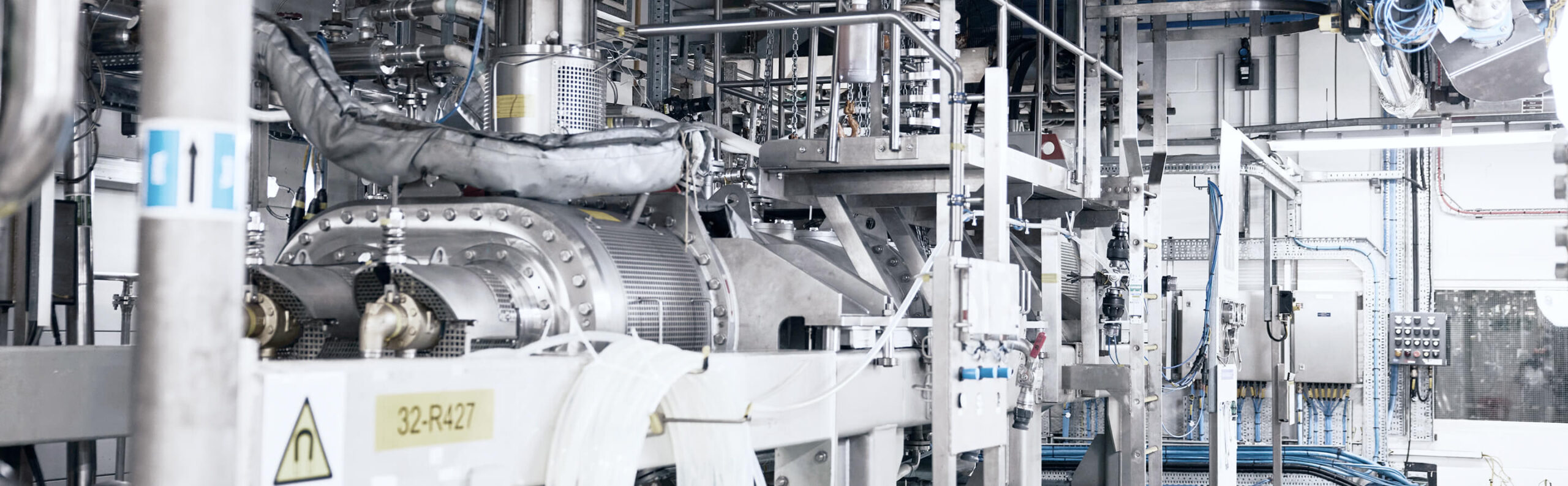

Explore how Codis applies its expertise in spray drying, microencapsulation, continuous granulation, final dosage forms, and functional products to meet your formulation and manufacturing needs.

Codis Insights & Updates

Stay current with the latest in particle engineering science and Codis articles and resources.

for Partnership

Connect with us to explore how our particle engineering, commercial spray drying, formulation, and advanced manufacturing capabilities deliver high-quality, dependable supply for even the most challenging products.