Continuous Granulation

Scroll

Advanced Continuous Granulation Technology

Our granulation technology combines multiple unit operations, including mixing, coating, hydrating, and homogenizing, into a continuous process that transforms raw powders into uniform, high-performance granules. Wet and dry ingredients are fed simultaneously, with precise control over shear, mixing intensity, and residence time to achieve consistent particle size, density, and flow properties.

Codis Continuous Granulation Advantages & Applications

Our continuous granulation capabilities offer clear advantages for tablets, bars, and powders, including:

Integrated multi-step processing

allows continuous mixing, coating, hydrating, and homogenizing functions to work seamlessly together for maximum efficiency and product quality

Concurrent ingredient feeding

meters multiple wet and dry ingredients simultaneously for consistent granule composition

Flexible process control

adjusts residence time, mixing intensity, and shear to meet exact product requirements

Continuous manufacturing

minimizes lot-to-lot variation, enables larger batch runs, and correspondingly reduces testing costs

Optimized particle properties

yield high-density granules with excellent flow characteristics, reducing dust, and facilitating streamlined downstream processing

Strategically engineered particles

improve mouthfeel and/or drug release

Experience, Quality and Trust

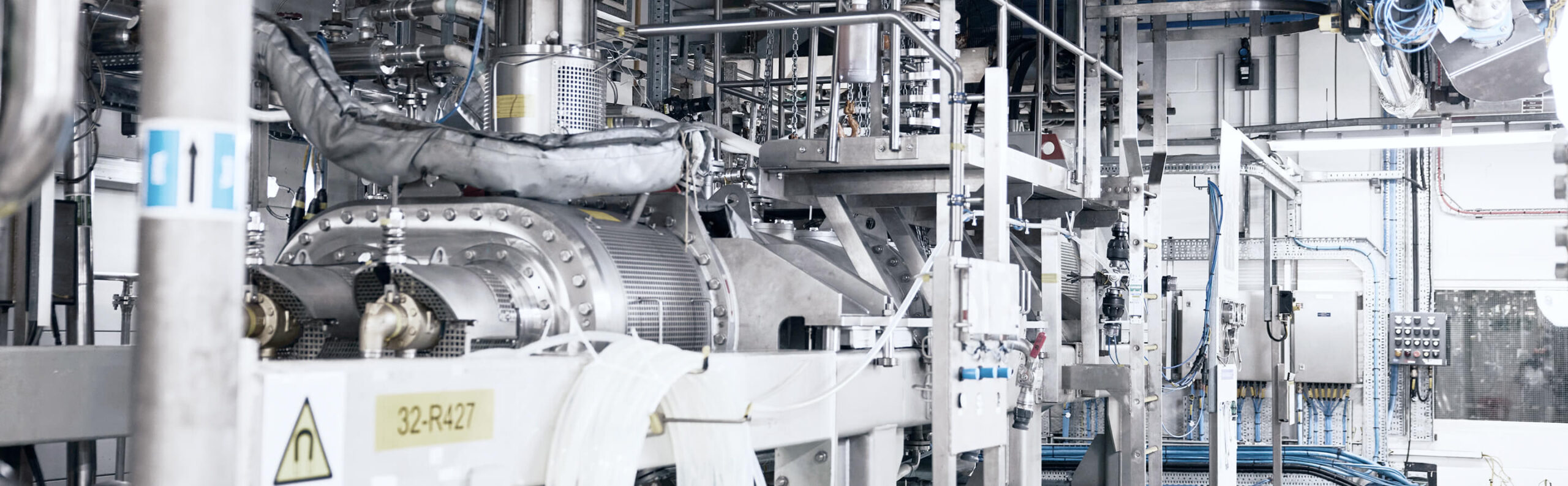

Facility Highlights

-

Manufacturing Facility:

St Louis, Missouri, USA

-

Total Annual Capacity:

1,750 metric tons

-

Minimum Batch Size:

3,000 kilograms

-

Typical Processing Rate:

50-1,000 kg/hr

-

Compliance:

The facility and its processes comply with US FDA 21 CFR Parts 210/211, 110/111, and 117, as well as EU drug certification standards.

-

Standard Products:

Direct compression calcium carbonate, Methylcellulose

-

Custom Products:

Wide variety of Rx, consumer health, and nutraceutical products. Contact us to get started.

Discover Codis

Explore how Codis applies its expertise in spray drying, microencapsulation, continuous granulation, final dosage forms, and functional products to meet your formulation and manufacturing needs.

Codis Insights & Updates

Stay current with the latest in particle engineering science and Codis articles and resources.

Connect with us to explore how our particle engineering, commercial spray drying, formulation, and advanced manufacturing capabilities deliver high-quality, dependable supply for even the most challenging products.