Organic & Polymer Chemistry

Scroll

High-Volume Continuous Industrial Flow Chemistry

Codis combines decades of process engineering experience with advanced flow chemistry expertise to deliver scalable, efficient, and safe continuous manufacturing. Our high-volume systems enable precise reaction control, faster optimization, and cleaner, higher-yielding processes, enabling consistent quality and sustainable production at commercial scale. Central to these capabilities are our LIST twin-shaft continuous kneader-reactors, integrated into our pilot and commercial-scale production plants. These reactors offer exceptional mixing and kneading behavior, effective self-cleaning properties, and efficient renewal of reaction boundary layers while maintaining low shear for high-viscosity, difficult-to-mix reactants and products.

Increase product quality and yield

More precise control of key reaction parameters such as mixing, heating, and residence time leads to better product yield and impurity control

Rapid analysis, optimization, and scale-up of chemical reactions

Testing a range of reaction variables is faster in flow processes and uses less substrate and reagent. Real-time analysis provides immediate feedback on the effect each variable has on reaction performance

Modular, customizable workflow

Flow chemistry equipment is highly modular, making it easy to configure equipment to meet the requirements of specific reactions

Improved process safety

Flow chemistry makes it significantly safer to handle hazardous or corrosive reagents and perform potentially dangerous reactions

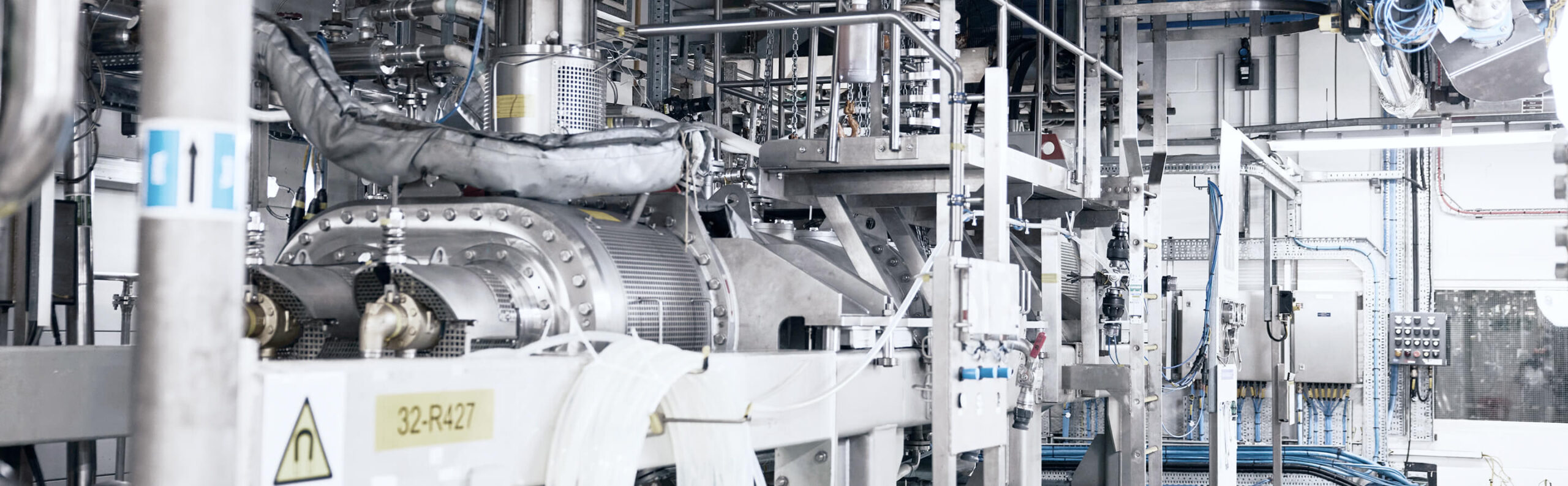

Pilot- and Commercial-Scale Production

Codis scales chemical processes from lab to large-scale commercial production with efficiency. Two state-of-the-art plants use cutting-edge flow chemistry for synthesis and purification, seamlessly integrating with spray drying for final isolation. Sustainability drives our operations, with proven success in implementing green, efficient, and resource-conscious manufacturing processes.

End-to-End Chemistry Support

From early material design and feasibility studies through scale-up and commercial production, Codis integrates organic and polymer chemistry into every stage of the development lifecycle. Whether you require a custom polymer, excipient or API, we have the chemistry expertise and facilities that delivers commercial success.

Contact UsDiscover Codis

Explore how Codis applies its expertise in spray drying, microencapsulation, continuous granulation, final dosage forms, and functional products to meet your formulation and manufacturing needs.

Codis Insights & Updates

Stay current with the latest in particle engineering science and Codis articles and resources.

Connect with us to explore how our particle engineering, commercial spray drying, formulation, and advanced manufacturing capabilities deliver high-quality, dependable supply for even the most challenging products.