Sustainability at Codis

Scroll

Codis UK Sustainability At-a-Glance

-

53%

reduction in CO₂ emissions

-

75% of processing water

Recapture system recycles and reuses up to

-

16,000 m2

on-site solar farm produces uo to 1.6 MW power generation

-

Zero waste-to-landfill

since 2017

-

ISO 14001 & ISO 50001 standards

HSE management system certified to internationally recognized standards

-

A Shared Commitment

We know our customers value sustainability, and so do we. As a CDMO serving global innovators, Codis aligns with your environmental goals while delivering the scientific rigor, speed, and reliability your programs require. No matter the product or process, we’re building a smarter, cleaner path to commercial success.

-

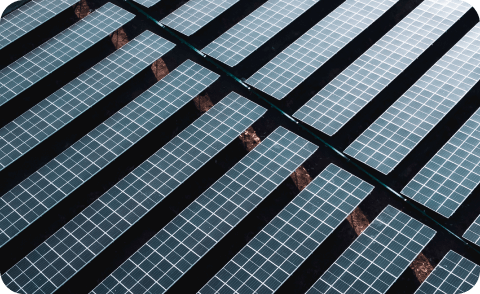

Renewable Energy That Powers Progress

Our Haverhill, UK facility features a 36,000 m2 on-site solar farm that directly powers site operations, reducing reliance on the power grid and minimizing the use of fossil fuels, thereby reducing our greenhouse gas emissions by more than 50%. This visible investment reflects our long-term commitment to sustainable energy and operational resilience.

-

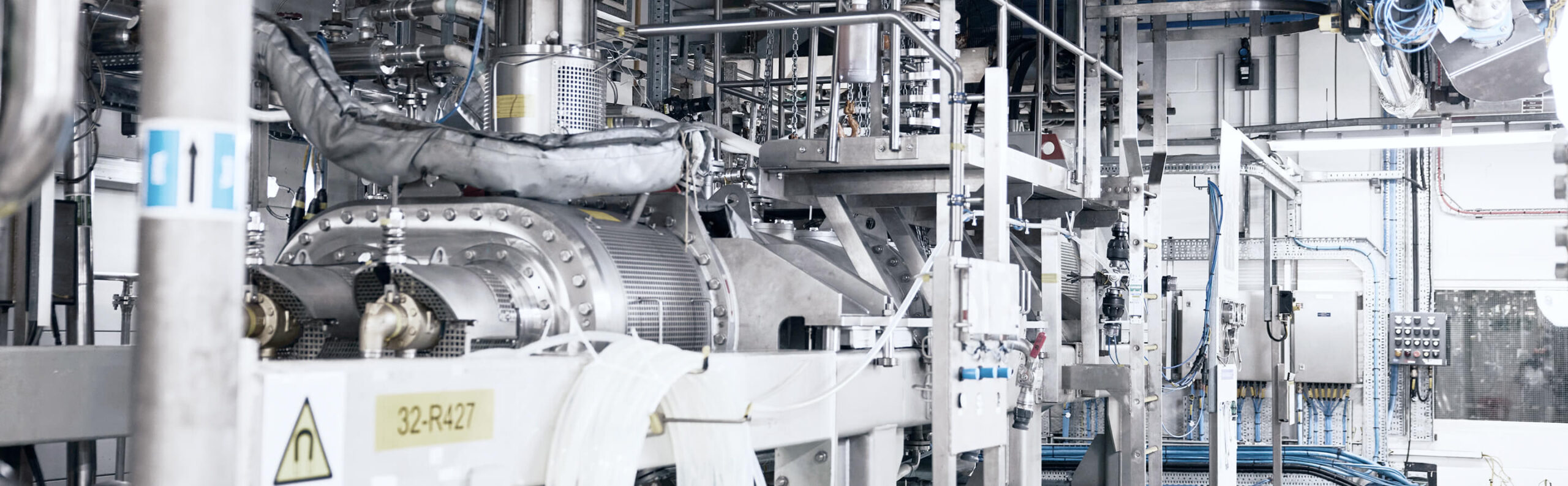

Solvent-Water Recycling Systems for Cleaner Manufacturing

Codis is built to manufacture commercial products with sustainability in mind. Our integrated solvent handling and recovery systems support the safe processing of hazardous and flammable materials while minimizing emissions and waste. Our solvent-water recycling systems ensure that environmental responsibility doesn’t come at the expense of performance or scalability.

Efficient Continuous Manufacturing

Sustainability is engineered into our process design. Specifically, our FDA-approved continuous manufacturing process for Sevelamer has resulted in:

25%

reduction in CO2/kg product produced

75%

of processing water is recycled and reused

E-factor of 1.1

reducing waste produced and the cost of disposal

25-fold

reduction of process mass intensity, improving yield, and reducing the cost of goods

Real-time monitoring and advanced process analytical technologies (PAT) enable precision control, helping us improve yield, reduce waste, and improve right-first-time metrics.

Discover Codis

Explore how Codis applies its expertise in spray drying, microencapsulation, continuous granulation, final dosage forms, and functional products to meet your formulation and manufacturing needs.

Codis Insights & Updates

Stay current with the latest in particle engineering science and Codis articles and resources.

Connect with us to explore how our particle engineering, commercial spray drying, formulation, and advanced manufacturing capabilities deliver high-quality, dependable supply for even the most challenging products.