Commercial-Scale Aqueous Spray Drying

Scroll

Aqueous Spray Drying Core Capabilities

Approach to Tech Transfer

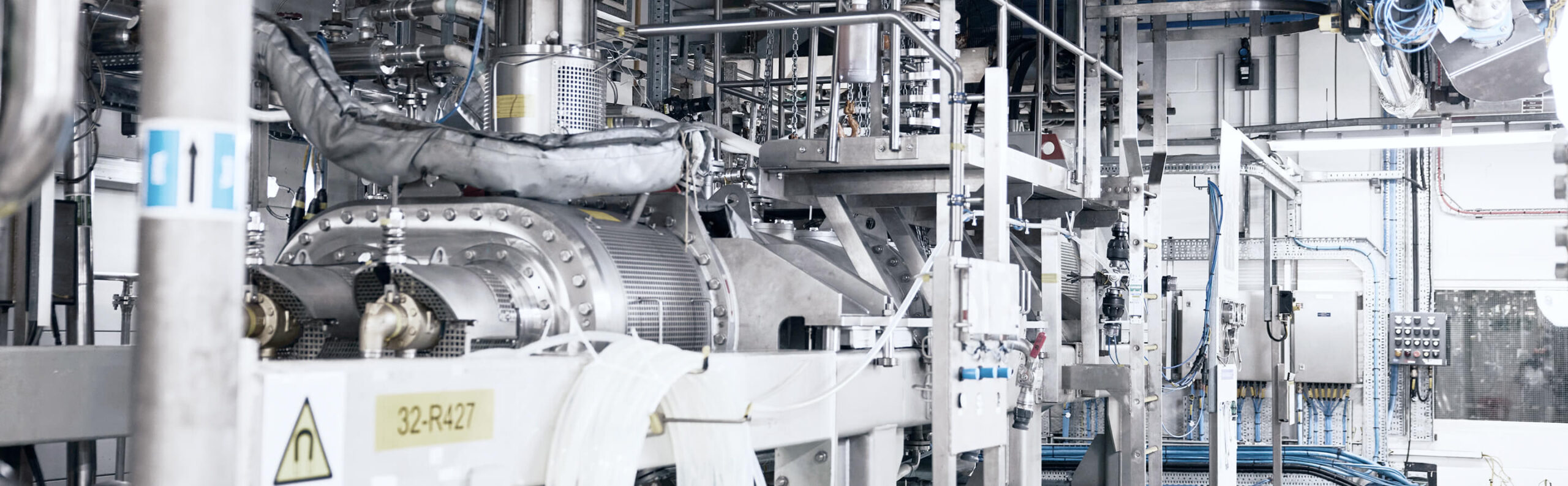

From gram-scale feasibility batches to sustained, multi-ton production runs on one of the world’s largest pharmaceutical spray dryers, Codis UK delivers capacity without compromise. Our commercial-scale infrastructure, harmonized process controls, and expert tech transfer teams ensure every process performs predictably as it moves from R&D to clinical supply to high-throughput commercial campaigns—whether you need a single engineering lot or ongoing global supply.

Analytical Expertise & Quality Control

Codis integrates comprehensive analytical testing with in-process monitoring to verify critical quality attributes at every step. Our Process Analytical Technology (PAT) tools enable real-time monitoring, supporting our spray drying facilities in Haverhill, UK, and Seymour, IN, USA, which operate under GMP-compliant systems to meet global quality standards.

Discover Codis

Explore how Codis applies its expertise in spray drying, microencapsulation, continuous granulation, final dosage forms, and functional products to meet your formulation and manufacturing needs.

Codis Insights & Updates

Stay current with the latest in particle engineering science and Codis articles and resources.

Connect with us to explore how our particle engineering, commercial spray drying, formulation, and advanced manufacturing capabilities deliver high-quality, dependable supply for even the most challenging products.